Report Overview

Featuring 31 tables and 13 figures – now available in Excel and Powerpoint! Learn More

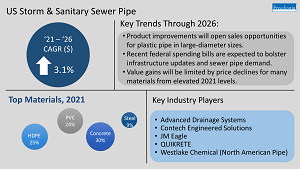

Through 2026, demand for storm and sanitary sewer pipe in the US is forecast to rise 3.1% per year to $8.2 billion, equivalent to 707 million linear feet. While growth in value terms is projected to decelerate slightly as average prices of plastic and metal pipe moderate from highly inflated levels in 2021, volume gains will accelerate, driven by:

Through 2026, demand for storm and sanitary sewer pipe in the US is forecast to rise 3.1% per year to $8.2 billion, equivalent to 707 million linear feet. While growth in value terms is projected to decelerate slightly as average prices of plastic and metal pipe moderate from highly inflated levels in 2021, volume gains will accelerate, driven by:

- increasing water and sewer construction, boosted by recent federal infrastructure legislation such as the Infrastructure Investment and Jobs Act

- increased spending on the construction and repair of highways, which tends to coincide with sewer and pipe installation or replacement

- improvement and repair activity on buildings, which will support gains for drainage pipe, especially in the commercial segment where drainage pipe is needed to prevent water accumulation in parking lots

- a number of trends in building construction – such as the increase in the number of bathrooms per building – that will place pressure on the existing sewer infrastructure, promoting replacement

Major Spike in PVC & Steel Prices in 2021 Leads to Record Year in Value Terms

In 2021, the average prices of PVC and steel sewer pipe surged 40% and 47%, respectively. The significant increase in prices was due to a number of factors including:

- major increases in raw material prices, as inflation reached the highest levels in the US in decades

- significant supply chain issues and shortages

These price increases led to a massive spike in value demand in 2021 that was boosted by elevated residential building construction, which further increased pipe demand above the available supply. However, sewer pipe demand in linear feet terms decreased in that year due to a pandemic-driven decline in state and local government spending on infrastructure construction.

Plastic Pipe to Gain Share in Large-Diameter Sewer Applications

Plastic pipe use dominates in storm and sanitary sewer applications because of its light weight, ease of handling, and corrosion resistance. In many cases, civil engineers and sewer professionals will select plastic pipe – instead of traditional concrete or steel materials – for repair and replacement projects because plastic products:

- are less costly in terms of both material price and installation

- are more suitable for trenchless installation and rehabilitation processes

While plastic has traditionally been uncompetitive in large diameters, improvements to resin formulations and processing will open new sales opportunities in these sizes.

Plastic

Demand by Resin

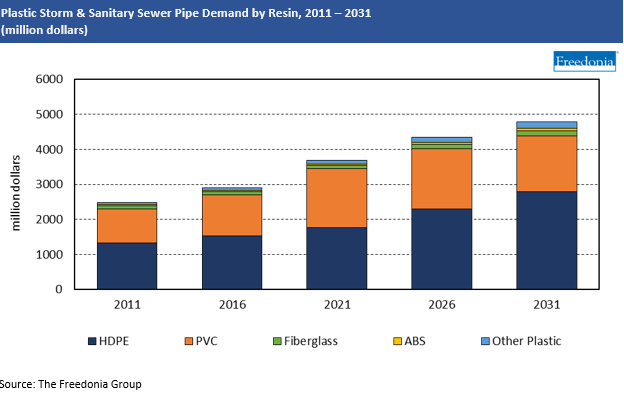

Demand for plastic storm and sanitary sewer pipe is forecast to rise 3.3% per year to $4.3 billion in 2026. In many cases, civil engineers and sewer professionals will continue to select plastic pipe – instead of concrete or steel materials – for repair and replacement projects because plastic products:

- are less costly in terms of material price and installation

- provide enhanced performance properties, especially in small and medium diameter applications

- are more suitable for trenchless installation and rehabilitation processes

While plastic is traditionally uncompetitive in large diameters, improvements to resin formulations and processing will open new sales opportunities in these sizes.

Among resin types, HDPE accounts for the largest share of storm and sanitary sewer pipe demand and is one of the fastest growing:

- For storm sewers, corrugated HDPE pipe offers comparable structural strength to traditional materials, but is lighter, easier to handle and install, and more resistant to damage caused by corrosive compounds and acidic soils.

- In sanitary sewer applications, HDPE pipe benefits from its simplified on-site fabrication and resistance to wear during installation, which helps ensure watertight joints to prevent water infiltration and sewer exfiltration.

Growth opportunities will be significant for large diameter HDPE storm sewers, as processors use more durable HDPE resin formulations to create pipe that features better crush resistance – an important consideration for these pipes, which must withstand heavy pressures and storm surges.

Advances will also be supported by the continuing use of PVC pipe in sanitary sewers. PVC’s corrosion resistance is a key selling point for infrastructure professionals, as PVC pipe does not require liners, coatings, or special hydraulic designs to keep lines full (and oxygen free), such as those required by ductile iron pipe. However, PVC pipe demand advances will be restrained by the fact that PVC, unlike HDPE, is generally not suitable for large diameter pipes. Thus, PVC pipe will not play as large a role in storm sewer applications.

Other plastic sewer and drainage pipe materials include fiberglass, ABS, and polypropylene:

- Fiberglass pipe is used in such harsh environmental conditions as beneath rocky terrain, on bridges, and underwater.

- ABS pipe is mainly used in applications requiring enhanced chemical, crush, and impact resistance.

- Polypropylene is a relatively new player in the US market but is growing in popularity due to its stiffness, which makes it easier to install in some areas than HDPE corrugated pipe.