Report Overview

Porcelain slab has seen its popularity skyrocket over the last decade.

Porcelain slab has seen its popularity skyrocket over the last decade.

This Freedonia industry study analyzes the $41.9 billion global countertops industry. It presents historical demand data (2013, 2018, and 2023) and forecasts (2028 and 2033) by product (solid surface and other cast polymers, laminates, engineered stone, natural stone, porcelain slab, other), market (residential, nonresidential), area of installation (kitchen, bathroom, other) and major global region and country. Annual historical data and forecasts are also provided from 2020 to 2027. The study also evaluates company market share and competitive analysis on industry competitors including Wilsonart, Cosentino, Caesarstone, VICOSTONE, Formica, Panolam, DuPont, and Cambria.

Featuring 299 tables and 113 figures – available in Excel and Powerpoint! Learn More

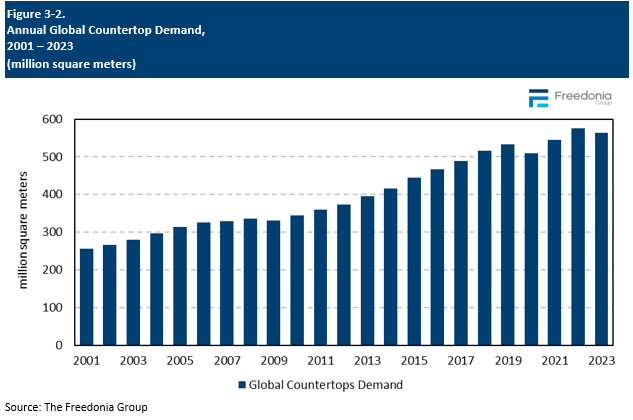

Global demand for countertops is forecast to increase an average of 3.0% per year to 652 million square meters in 2028, valued at $49.5 billion. Market advances will be supported by rising installations of countertops – which continue to be selected over freestanding or wall-mounted fixtures in kitchens and bathrooms – for both residential and nonresidential applications. Additionally, demand will be bolstered by increased residential remodeling, as countertop replacement remains one of the most popular ways to update kitchens and bathrooms.

While real demand growth is expected to accelerate through 2028, market value will decelerate as prices for most countertop materials moderate from elevated 2023 levels that resulted from pandemic-related price spikes in 2021 and 2022.

Porcelain Slab Taking Advantage of Recent Weakness in the Engineered Stone Market

Porcelain slab has seen its popularity skyrocket over the last decade due to its aesthetics, durability, and stain resistance, and the material is expected to double its share of the global countertops market by 2028. While its market size will remain small relative to some of the other major countertop materials, it is making inroads among consumers and builders who would have previously chosen engineered stone, which offers many of the same performance advantages of porcelain slab.

After nearly a decade of double-digit growth, engineered stone demand plummeted in 2023, due primarily to a weak residential market in the US (the largest user of engineered stone globally). However, potential future difficulties for this material were signaled by Australia, which passed a national ban (to begin in mid-2024) on engineered stone products. While engineered stone demand is expected to grow at a solid rate throughout the forecast period, there is the possibility that this material could see more widespread regulation, with consumers potentially opting instead for porcelain slab in even greater numbers than expected.

Developing Markets for Countertops Offer Significant Sales Opportunities

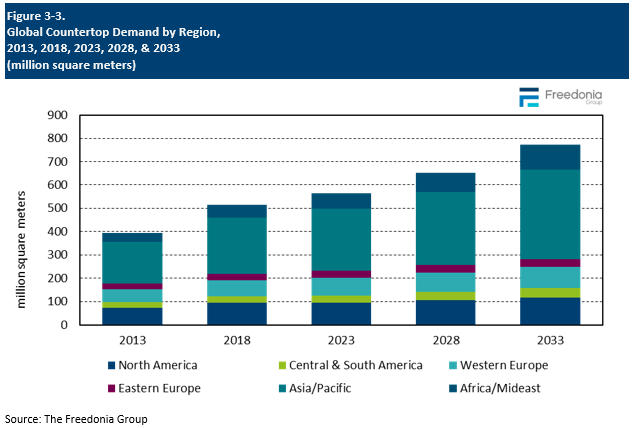

Developing countries with strong building construction activity and relatively low countertop usage rates – including a number of Southeast Asian and African countries – will generally see the fastest demand growth going forward. Rising incomes will prompt consumers or building owners to improve their existing living spaces or build more modern housing. For some, these improvements will include a shift from freestanding furniture pieces and wall-mounted fixtures to fitted kitchens and bathrooms with cabinets, which often have countertops installed with them.

Historical Market Patterns

Countertop demand is driven by many factors, including:

-

local economic activity, personal incomes, and standards of living

-

new housing construction

-

single-family residential remodels, which often include the replacement of countertops or the addition of a bathroom, outdoor kitchen, or wet bar

-

commercial building construction

-

shifting consumer tastes (like the move toward countertops with a more natural stone aesthetic and away from laminates), which can result in increased demand in the residential remodeling market

-

the popularity and use of competitive products, such as furniture with integrated countertops

The COVID-19 pandemic and its aftermath made the global countertops market more volatile, with a decline in 2020 and exceedingly fast market value growth in 2021 and 2022 as supply chain issues and high raw material costs caused countertop prices to skyrocket. Following these high levels of demand and price increases, the market moderated significantly in 2023.

Regional Demand Trends

Demand by Region (square meters)

Global demand for countertops (also called benchtops or worktops in some parts of the world) is forecast to rise 3.0% per year to 652 million square meters in 2028.

Countertop demand varies on a regional and country-by-country basis, influenced by:

-

the building construction market, including construction activity, building stock, and building size

-

existing home sales, as there is more countertop demand in countries with frequent existing home sales as a good deal of home remodeling is spurred by the acquisition of an existing structure decorated to someone else’s tastes or having upgraded a room prior to sale

Sales of countertops in most developing countries are projected to increase faster than in the more mature markets in the industrialized world. Rising incomes in India and other Asia/Pacific countries, and the Africa/Mideast region will lead to increasing demand for countertop materials. However, the small size and simple construction of housing in many of these regions may continue to limit the amount of space dedicated to countertops in kitchens and bathrooms.

Countertop suppliers will also benefit from growing construction activity in the nonresidential sector – where usage is rising from a relatively low level – as less expensive shelving units are more frequently used in these markets.

Materials Overview

Demand by Material (Square Meters)

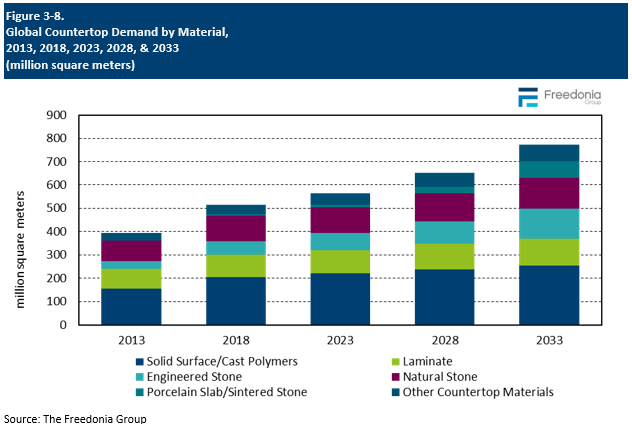

Global demand for countertops is forecast to rise 3.0% per year to 652 million square meters in 2028:

-

Solid surface countertops hold the largest share of the global market in area terms and will retain the leading position, supported by their widespread use in many developing markets in the Asia/Pacific region.

-

Engineered stone will grow at an above average pace due to expanding manufacturing capacity and its wide range of aesthetic options and favorable performance properties. However, engineered stone will continue to face intense competition from porcelain slab products.

-

Laminates will grow at a below average rate, as they continue to lose market share in North America and Western Europe to higher-end options with superior aesthetic properties.

Market Value

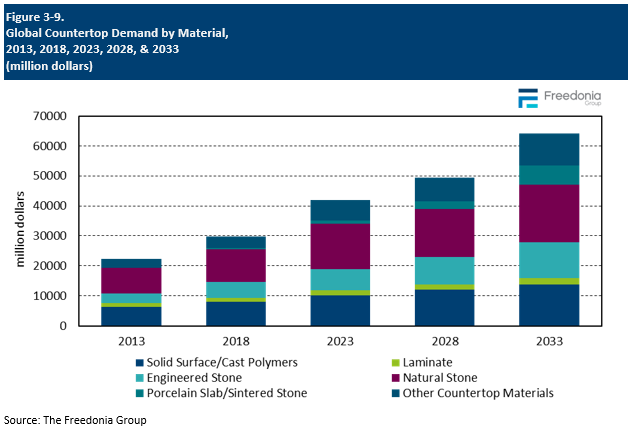

Global demand for countertops is expected to reach $49.5 billion in 2028 on annual gains of 3.4%. Value gains will be supported by:

-

preferences generally shifting to more aesthetically pleasing materials that command higher average prices

-

rising income levels in developing countries, leading to increased remodeling activity where homeowners trade up to higher-value countertops like granite, marble, or engineered stone

-

less expensive laminates losing market share while engineered stone use grows at healthy rates in the highly developed North American market

Further gains will be restrained by average global prices decelerating from their relatively high 2023 bases, which were mostly attributable to inflationary pressures. Furthermore, prices for natural stone materials and laminates are expected to decline during the forecast period.

In dollar terms, natural stone had the largest share (36%) of the global countertop demand in 2023. Porcelain slab and sintered stone products accounted for the smallest share of value demand despite their high average prices, primarily due to their low – but rapidly rising – sales volumes. However, the market value for porcelain slab countertops is projected to surpass laminates through 2028.

Installation Costs

Installation costs have a major impact on the final price of countertops, as DIY activity in the countertop industry is rare due to the difficulty of removing countertops and then properly cutting and fitting the replacement countertop materials.

Installation costs vary based on the countertop material and can greatly inflate the overall price of a countertop installation. If countertops with lower material costs are expensive to install, they can become less competitive with both higher priced and lower priced materials that have lower installation costs.

For example, laminate sheets can be purchased at the lowest price of all major countertop materials. However, the final installation cost of laminate countertops is just slightly below that of the more expensive solid surface material, which makes solid surface a more attractive option as consumers can trade up to a higher quality product for only a few dollars more per square foot when installation costs are taken into account.

Among the materials with the highest average installation costs are:

-

engineered stone

-

granite

-

marble

- porcelain slab